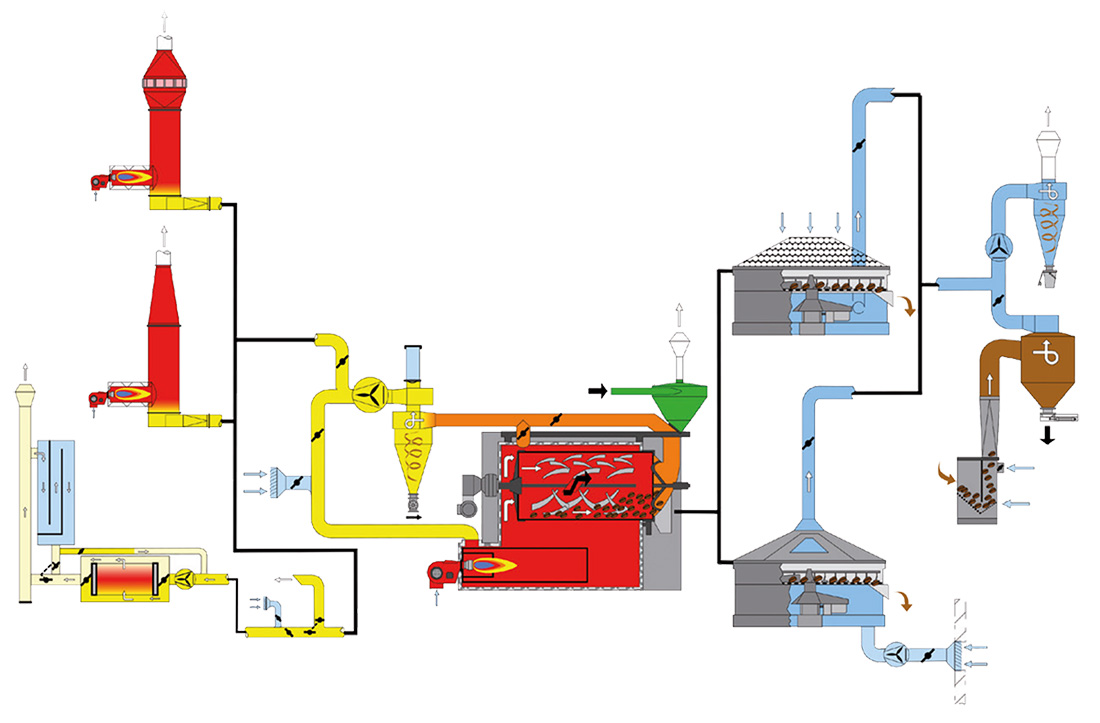

The heart of PROBAT’s NEPTUNE drum roasters is a horizontally lying roasting drum which is equipped with a rotary drive. Shovel blades circulate the coffee beans during the roasting process. The flame of a burner generates the energy for the roasting air which is guided both through as well as around the roasting drum by means of flaps. As such, heat is applied through conduction via the bean’s contact with the roasting drum as well as through convection via the hot incoming air. The addition of water systematically ends the roasting process while simultaneously precooling the roasted coffee.