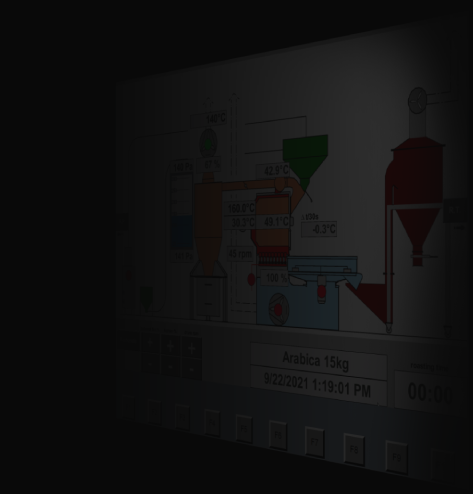

Thermocouples for recording machine- and process-related data enable optimum control over the roasting process for constant and reproducible roasting results.

The extended batch size range, the infinitely variable burner, frequency converters and the targeted airflow by means of the traditional "aroma wheel" allow maximum flexibility in the aroma development of different coffee types.

The classic look can be individually rounded off by adapting different design parts according to personal preference, unique for every roastery!