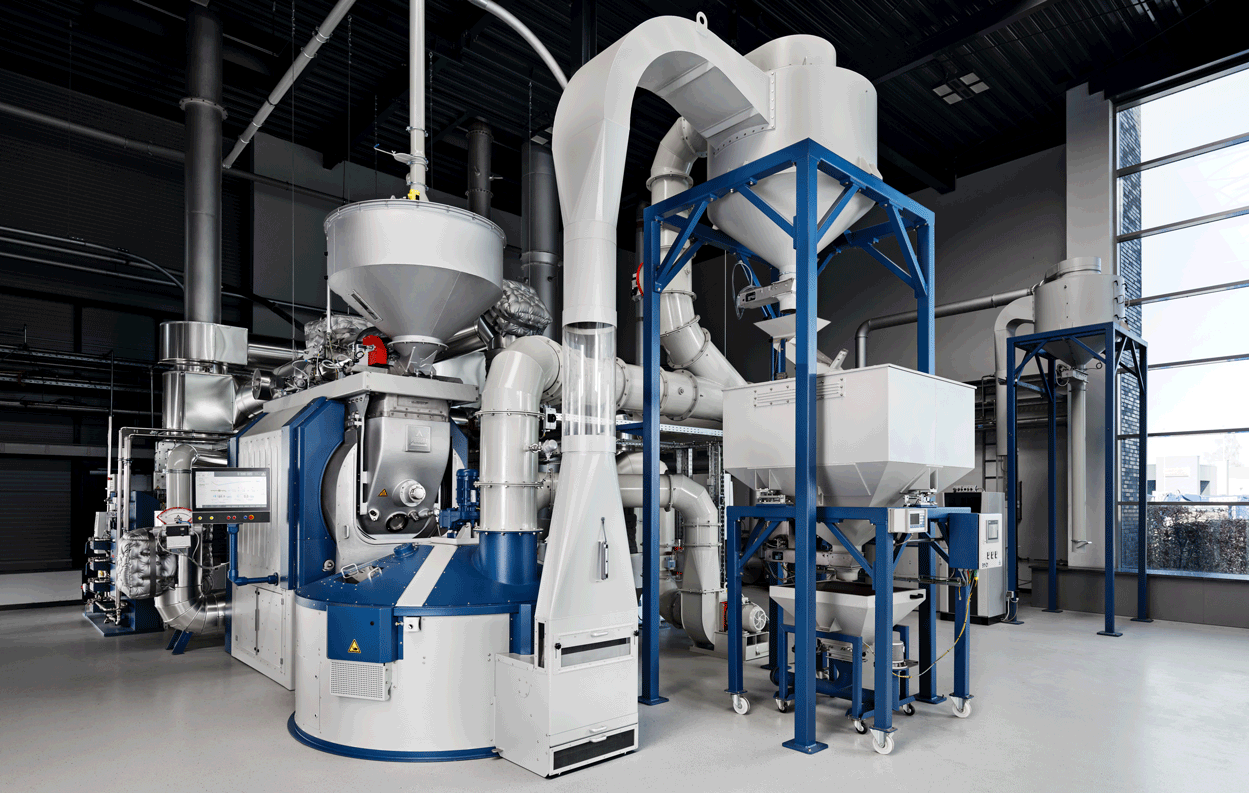

In hygiene-critical production environments, avoiding contamination of the end product is a key requirement. Therefore, the selection of the right materials, as well as the geometric design of the operating equipment, are paramount for clean production processes. The cleaning-friendly-designed parts and components of the NEPTUNE 1000 allow for simplified accessibility and easy maintenance, thus ensuring maximum availability of the roasting machine.

The future-oriented new control solution ensures reproducibility of roasting results and maximum production reliability.

The cleaning-friendly design of parts and components and the relocated maintenance points and inspection openings reduce downtimes to a minimum.

The modular design of the NEPTUNE 1000 covers the most-demanding customer requirements. The extended roasting time and batch size range, as well as frequency converters for all drives, ensure maximum flexibility in the aroma development of different coffee types.

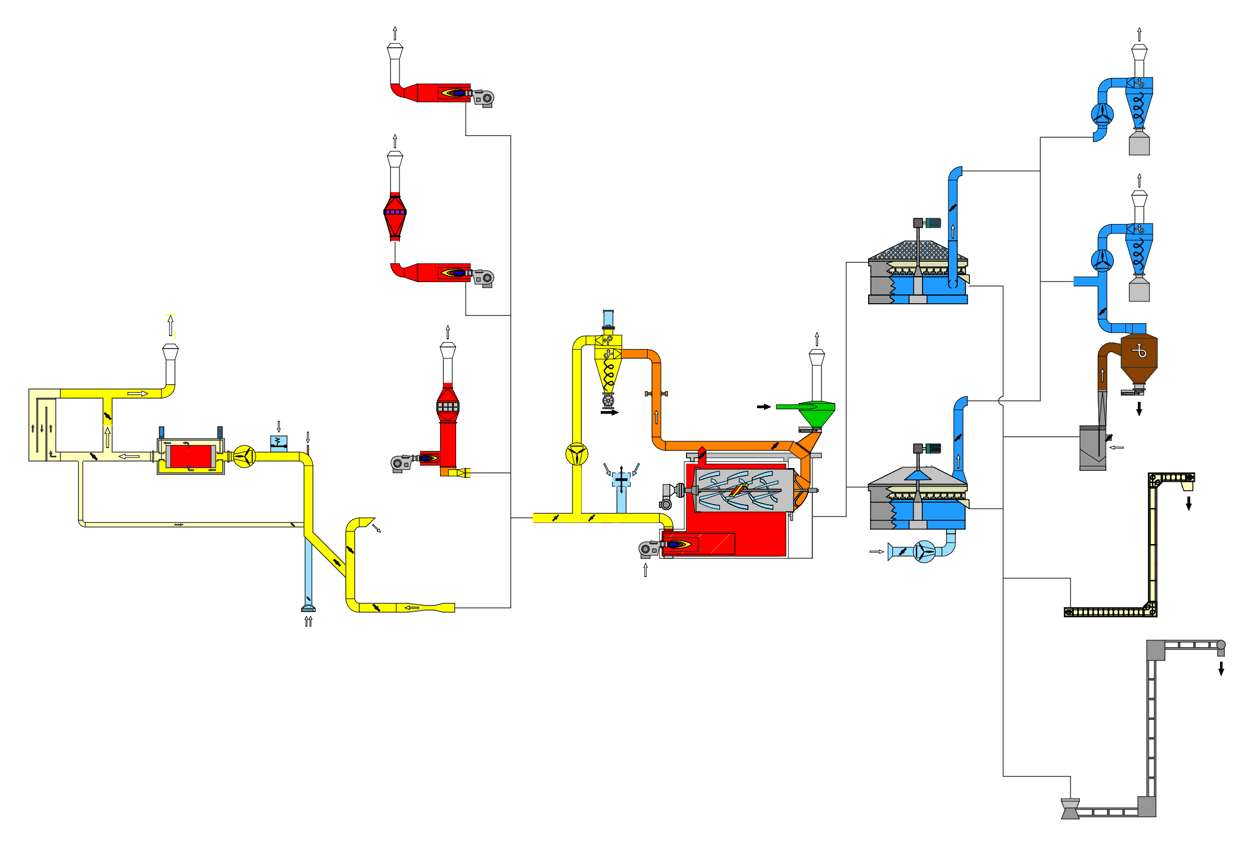

High-performance cyclones, heat energy recovery systems, and modular exhaust air treatment technology ensure maximum energy efficiency and reduce pollutant emissions to a minimum.

The NEPTUNE 1000 is equipped with the next-generation control solution PILOT ROASTER 2020. It is a web-based application with an optimized, intuitive HMI, that enables roasters to modify vital roasting parameters by touch, thus providing a completely new user experience focusing on essential information to monitor and control the roasting process. All data relevant to production are saved, allowing it to be accessed and analyzed at any time. The Reflex Automatic function ensures reproducibility of roasting profiles by eliminating external influences such as varying batch sizes, green coffee moisture, or ambient temperature. For more details on the pioneering PROBAT control solutions please also see Control Systems | PROBAT.