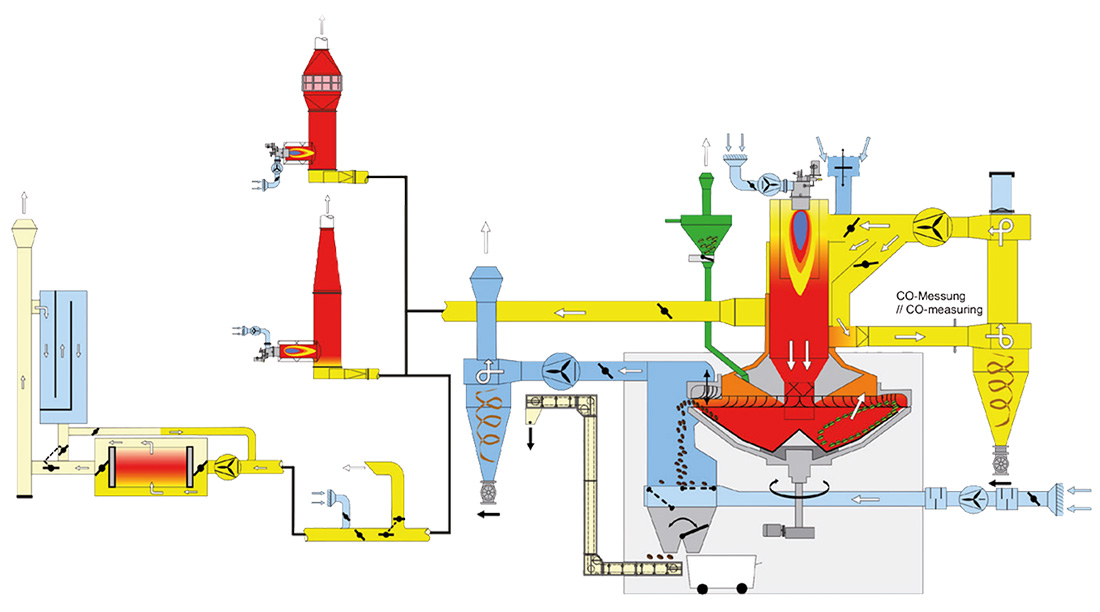

The distinguishing characteristic of the PROBAT SATURN centrifugal roaster is the rotation of the roasting bowl which is equipped with a lamellar ring around the vertical axis. In this manner, the green coffee is mixed gently during the roasting process. Hot air is guided into the roaster through the center of the bowl, and as a result, the heat is transferred evenly and the beans are roasted homogeneously. The result is a particularly uniform bean appearance. In this context, the quantity of air needed for the roasting process can be reduced to an absolute minimum. The addition of water systematically ends the roasting process while simultaneously precooling the roasted coffee.