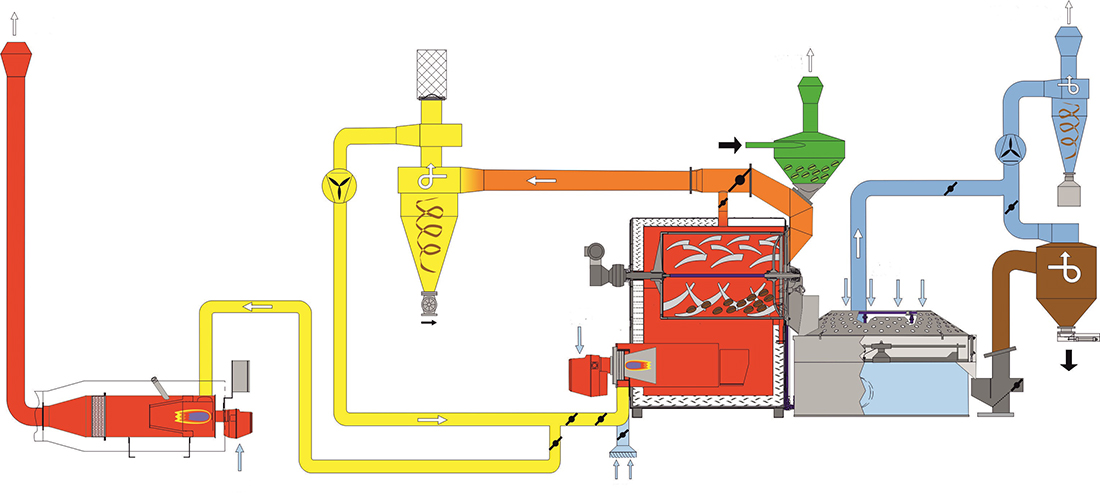

The heart of PROBAT’s Px 120 drum roaster is a horizontally lying roasting drum which is equipped with a rotary drive. Shovel blades circulate the coffee beans during the roasting process. The flame of a burner generates the energy for the roasting air which is guided both through as well as around the roasting drum by means of flaps. As such, heat is applied through conduction via the bean’s contact with the roasting drum as well as through convection via the hot incoming air.

The Px 120 drum roaster is equipped with the PILOT Roaster Excellence 2020 control system. It is a web-based application, which features an intuitive HMI, enabling roasters to modify vital roasting parameters by touch. The application is programmed using modern web technologies, which allow access from different devices and operating systems.

Different PROBAT systems make it possible to clean and reuse the thermal energy released during the roasting process. They are specifically tailored to the respective roasting process.

PROBAT safety technology goes far beyond standardized requirements. We offer safety components that guarantee maximum process security.